TL;DR:

Traditional lattices and minimal surfaces were a good start, but they were often limited by:

- Directional weakness (failing under multi-directional loads).

- Lack of tunability (hard to generate continuous grading).

- Envelope compromises (distorting boundaries in complex part).

The Solution: Adaptive Density Minimal Surfaces (ADMS)

- Varies material density based on stress or load.

- Uses dual chambers for lightweight, isotropic behavior.

- Preserves complex part envelopes (Boundary Conformance)

Engineers can now place strength exactly where it's needed, enabling truly lightweight, isotropic, and multi-functional parts for critical fields like aerospace, medical, and thermal management.

Over the past decade, lattice and minimal surface geometries have transformed how engineers design lightweight structures. From aerospace brackets to medical implants, these geometries promised lower weight and higher efficiency. Yet if we're honest, in practice, they often fall short. Every engineer who has tried to optimize a bracket knows the drill: lattices can be directionally weak, some minimal surfaces are a pain to tune, and neither gives you that precise control you need over stress.

The good news? Adaptive Density Minimal Surfaces (ADMS) bridges that geometric elegance with real-world engineering performance.

The Limits of Traditional Lattices

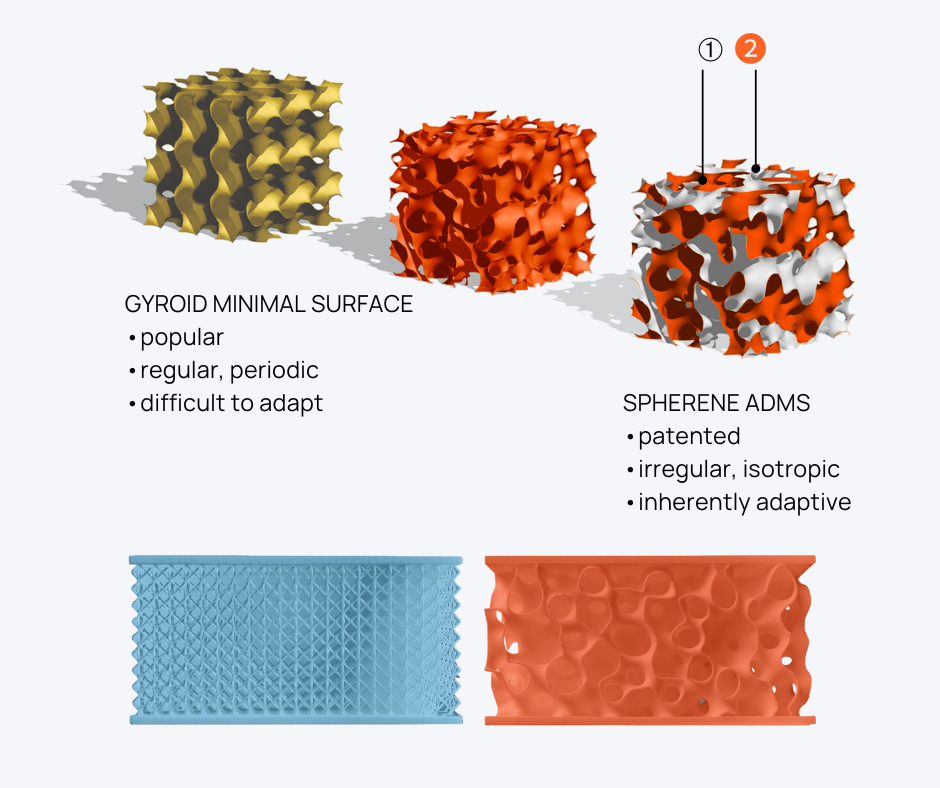

Lattices like gyroids are popular in additive manufacturing. They offer repeatable unit cells, predictable porosity, and reduced material usage. But they come with limitations:

- Directional weakness: Lattices often perform well along some axes but fail under multi-directional loads.

- Boundary compromise: Fitting lattice geometries to complex part shapes often distorts cells or leaves gaps, affecting performance.

- Limited adaptability: Once a lattice is defined, its mechanical properties are essentially locked in. There’s little room to locally tune stiffness, strength, or compliance. Merging lattices into one often introduces sharp transition interfaces and thus mechanical weak points.

Now, minimal surfaces got us closer, they offered that smoother stress distribution we craved and theoretical isotropy. But if you've worked with them, you know the tuning problem is still a killer. Most implementations are uniform, leaving engineers to compromise between weight savings and structural performance.

Enter ADMS: Design Strength Where It Matters

ADMS solves these challenges by placing material exactly where it’s needed. Building on minimal surface principles, ADMS adds adaptive density, dual chambers, and precision envelope control, and several key differentiators:

Isotropic: ADMS structures provide proven, uniform mechanical behavior in all directions, a key differentiator from directionally weak lattices.

Adaptable: Local thickness and density can be tuned for performance or manufacturing constraints.

Certifiable: Proven, predictable, and repeatable performance in aerospace, medical, and industrial applications.

Self-supported: Structures are print-friendly, reducing or eliminating the need for supports in additive manufacturing.

Key innovations include:

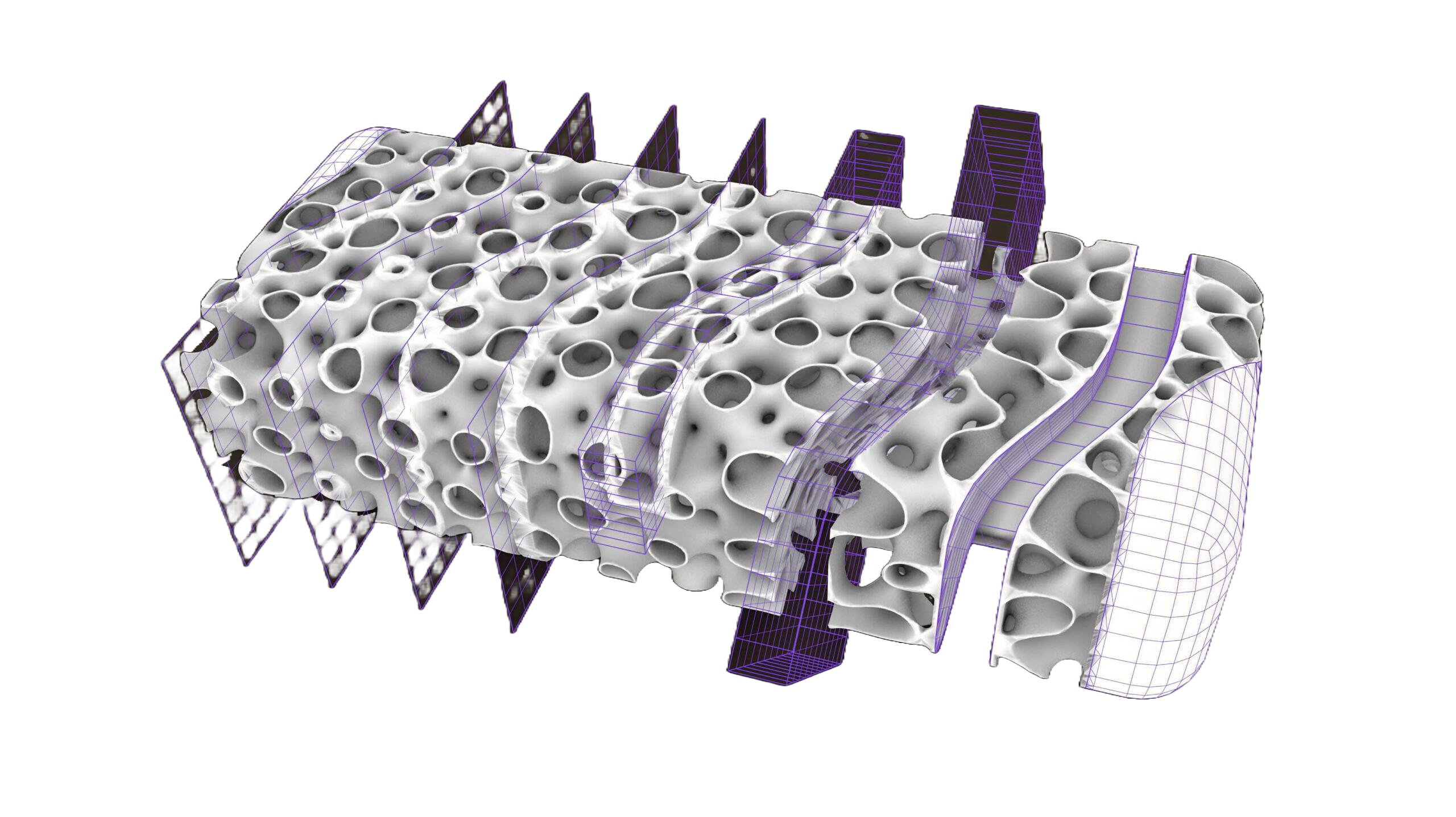

- Density/Thickness Fields: Instead of uniform density/thickness, ADMS varies material density/thickness across the surface based on stress, thermal load, or other design criteria.

- High Specific Surface Area:

The dual-chamber ADMS geometry creates large internal surface area for efficient heat transfer in compact designs. - Boundary Conformance: This is a big one. It means the surface structure doesn't compromise and perfectly fit in the complex outer shape of your part. You get to keep your design exactly as it was intended, even with intricate internal density variations.

Compared to traditional lattices, Spherene ADMS also enables:

- Faster design cycles: Optimized structures generated automatically in CAD.

- Multi-functional parts: Combine stiffness, vibration damping, acoustic tuning, and thermal management.

- Sustainability by design: 40–85% weight reduction, less material waste, lower CO₂ footprint (case-dependent).

- Printer- and material-agnostic: Works with metals, polymers, ceramics, and composites.

The result? Parts that are strong where they need to be, lightweight where they can be. And critically, they're compatible with complex geometries.

ADMS in Action

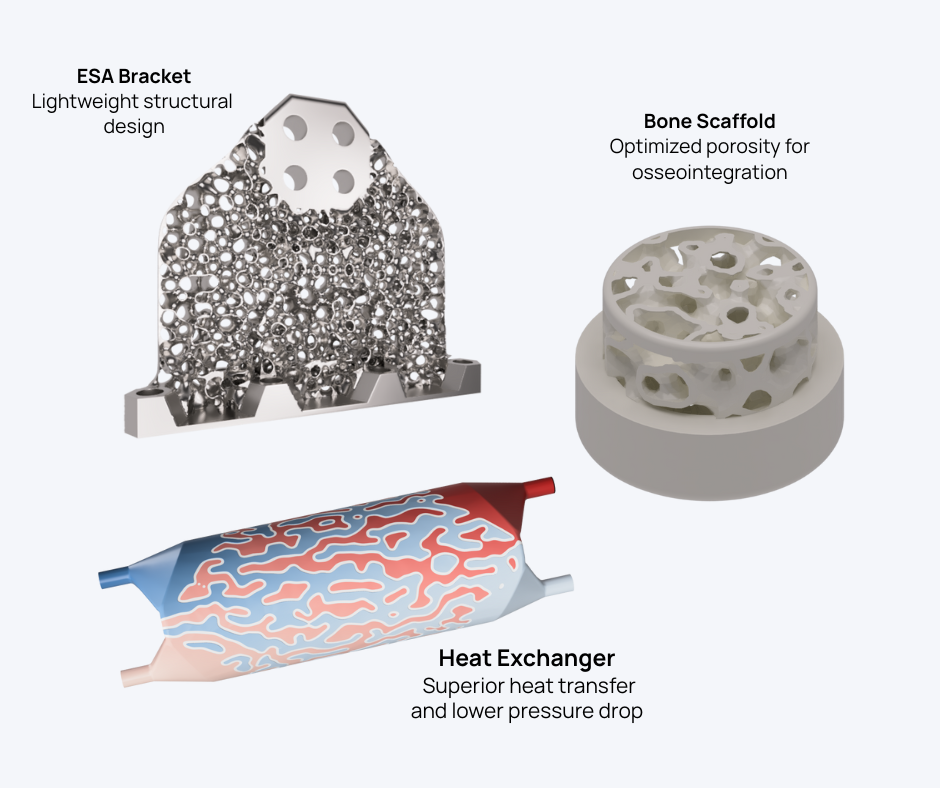

ADMS is already showing measurable advantages across industries:

- Aerospace: Lightweight brackets with uniform stress distribution outperform traditional lattices in mechanical testing.

- Medical Implants: Structures support bone growth while reducing stress shielding.

- EV Thermal Management: Internal adaptive channels optimize heat dissipation without sacrificing the design envelope.

Even where traditional lattices or minimal surfaces seemed sufficient, ADMS delivers predictable, tunable performance, reducing both trial-and-error in design and material waste in additive manufacturing.

ADMS in Practice: Opportunities for Engineers and Designers

ADMS isn’t just another design trend, it represents a fundamental shift in how engineers approach geometry: moving from rigid, repeating unit cells to flexible, continuous surfaces that adapt to the needs of each part. Designers can now:

- Precisely control stiffness and compliance throughout a part

- Ensure isotropy where it matters most

- Integrate additive manufacturing-friendly infill structures

- Explore multi-functional parts that combine strength, cooling, or damping

This approach opens doors to entirely new applications, ones where traditional lattices simply can’t deliver.

Looking Ahead

ADMS lays the groundwork for the next wave of additive manufacturing innovation. But this is just the beginning: new geometries, like SphereneHEX, expand the principle of adaptive surfaces into thermal management and multi-functional applications.

In our next post, we’ll take a closer look at how ADMS works under the hood, from density fields to dual chambers, giving engineers the insight they need to apply this technology in their designs.

Explore the potential of Adaptive Density Minimal Surfaces in your next project.