Adaptive Density Minimal Surfaces, or ADMS, give engineers a new way to shape mechanical behavior inside a part. Instead of relying on unit-based lattices or manually tuned internal structures, ADMS builds geometry from continuous minimal surfaces that can be controlled through fields. This lets you adjust stiffness, density, thermal exposure, vibration response, and local strength directly inside the part without breaking continuity or introducing weak transitions.

This blog explores how ADMS actually works behind the scenes. We take a closer look at density fields, dual chambers and envelope adapting, and how these three elements let you control internal architecture in a way that is both predictable and manufacturable.

Density Fields: Local Control Inside a Continuous Surface

A density field is what drives most of the functional behavior in ADMS. By defining higher or lower values in different regions, you can tell the surface where it needs to be denser or more porous. Denser regions are stiffer and stronger, while the other regions are lighter and more compliant.

The changes of density happen continuously and smoothly along the envelope geometry. There are no stitched units, no abrupt transitions, and no hotspots created by joining different lattice types. The entire internal structure responds to the field as a single system, avoiding the creation of internal mechanical weak points.

From an engineering standpoint, this is useful when you need gradual reinforcement, controlled deformation, or highly customized load paths. It also gives designers predictable results because the performance shifts are directly tied to the field you define.

- Aerospace brackets and mounts

Local reinforcement where load peaks occur while keeping the rest of the component ultra-light. - Medical implants

Denser regions where osseointegration loads are highest and more porous regions to reduce stiffness mismatch. - Consumer products

Tunable impact zones for helmets or protective gear without manually defining multiple lattice types.

ESA bracket - The bracket uses a continuously varying density, increasing local surface thickness in highly stressed regions while reducing material where loads are lower.

ESA bracket - The bracket uses a continuously varying density, increasing local surface thickness in highly stressed regions while reducing material where loads are lower.

Dual Chambers: Stable Internal Behavior with Extended Surface Area

.png?width=1080&height=439&name=gradient_chambers%20(1).png)

ADMS naturally forms two continuous but separated chambers. This dual-chamber nature is part of how minimal surfaces behave, and it brings a few practical benefits.

The two chambers run continuously through the part, allowing airflow, fluid distribution, or force transmission to occur without the blockages or dead zones commonly found in repetitive lattice structures. Meanwhile, the high specific surface area of the two chambers gives ADMS advantages in functional applications such as energy absorption and heat distribution. The result is a balanced internal layout that supports both mechanical and functional goals.

- Heat management components

The large surface area helps spread heat through conduction or convection inside complex housings. - Automotive NVH components

Dual chambers can dissipate vibrations or noise more effectively than unit-cell lattices. - Sports equipment

Better balance between strength, stiffness, flex and shock absorption in frames, protective inserts or crushing zones.

.png?width=1470&height=582&name=HEX%20cross-ing%20(1).png)

SphereneHEX: Heat exchanger with flow geometry that has Intertwined dual chambers that guide fluid separately, optimizing heat dissipation and material efficiency.

Envelope Adaptive: Keeping Geometry Inside Your Design Intent

ADMS adapts itself to the envelope you set. The envelope defines the outer boundary, and the minimal surface fills it in without violating your part's geometry.

This means that ADMS can be integrated into complex shapes, thin walls, ribbed profiles, or organic forms without any modification to the envelope design or complicated manual manipulation of the internal structure. The surface simply adapts to the given geometry with a few simple clicks.

For engineers, envelope control makes iteration faster. For designers, it removes the need to simplify aesthetics or external profiles just to make an internal structure possible.- Tooling and molds

Integrating ADMS inside thin or curved mold sections where conventional lattices cannot follow the shape. - Robotics and automation

Lightweight end-effectors or structural arms where every gram matters and geometry is constrained. - Wearables and ergonomic devices

Internal structures that closely follow organic, human-facing surfaces while remaining breathable and flexible.

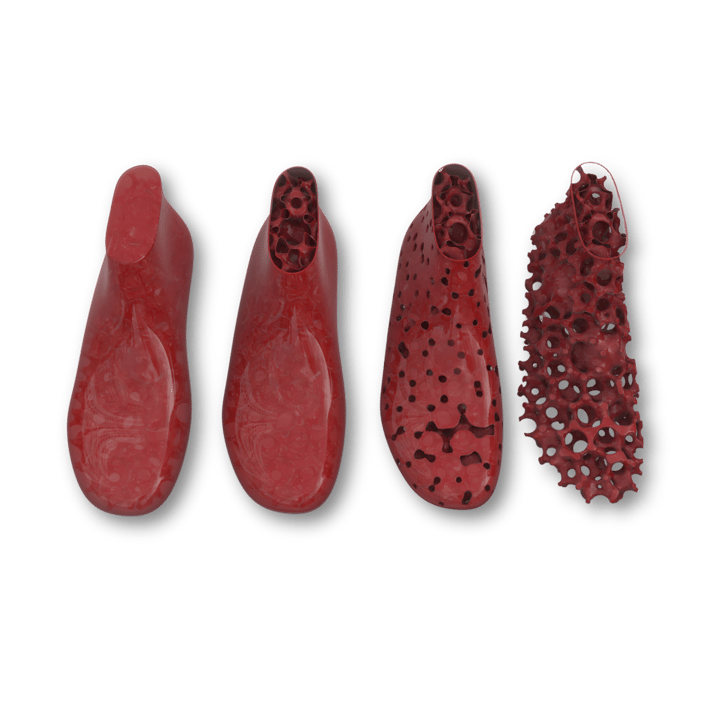

Shoe last exploration: Left to right - Spherene as infill, partially closed, thickened up and as lattice.

ADMS combines isotropy, adaptability, and manufacturability in a way that traditional lattice structures often struggle to match. The continuous surface geometry gives you predictable performance. Density fields let you tune properties as needed. The dual chambers provide a high surface area and multifunctionality. And envelope control ensures the structure always matches your part shape.

Taken together, these elements create a practical path toward lighter parts, more consistent outcomes, and shorter design cycles in additive manufacturing.

Bring ADMS Into Your Workflow

You can download Spherene’s integration for CAD platforms and start generating ADMS directly into your existing design tools. If you have a unique application or a part that needs specific functional tuning, contact us and we can help you explore what ADMS can achieve in your case.