SUPERIOR HEAT DISSIPATION

Cooler systems.

Higher performance.

.png?width=300&name=HEX%20cross-ing%20(1).png)

ACROSS AUTOMOTIVE, ELECTRONICS, ENERGY SYSTEMS AND AEROSPACE EFFICIENT THERMAL MANAGEMENT REMAINS A CRITICAL BOTTLENECK

Conventional designs — including heat exchangers, evaporators, cooling plates, and intricate cooling channels in molding — are constrained by issues such as suboptimal thermal efficiency, elevated pressure drop, and susceptibility to powder entrapment.

SUPERIOR HEAT DISSIPATION SOLUTIONS WITH SPHERENE

ADMS generates continuous, high-surface-area channels that maximize heat transfer while staying clog-free and lightweight.

Key Benefits

- Higher Thermal Efficiency

Maximizes heat dissipation in compact, lightweight geometries. - Predictable Performance

Simulation-verified flow and pressure behavior under varied conditions. - Self-Draining

Channels Minimizes clogging and ensures long-term reliability. - Compact, Lightweight Designs

Optimized for minimal footprint without sacrificing performance.

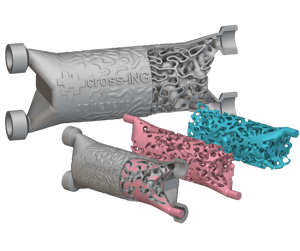

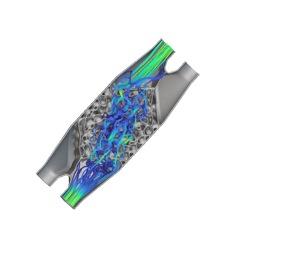

HEAT EXCHANGER (HEX)

Specifications

- Boosted Thermal Efficiency

ADMS expands the effective surface area, enhancing heat transfer and keeping systems cooler. - Lower Pressure Drop

Smooth ADMS pathways ensure steady, clog-free fluid flow for consistent performance. - Compact, High-Performance Design

Delivers outstanding results in a smaller footprint, saving space without compromising efficiency. - Predictable & Reliable

Flow geometry provides consistent flow and thermal behavior, making further validation easier and more reliable.

Results

- Spherene's ADMS technology significantly enhances heat exchanger performance by effectively doubling the effective surface area, leading to substantially improved heat dissipation efficiency.

- The resulting compact design reduces volume while maintaining or exceeding thermal performance.

- The specialized self-draining ADMS channels prevent clogging and ensure optimal flow conditions, increasing the reliability and consistency of the heat exchange process.

Visuals: Heat Exchanger models created in

partnership with cross-ING

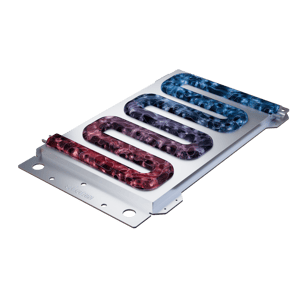

AUTOMOTIVE

EV COOLING PLATES

- High Thermal Efficiency

Spherene maximizes heat transfer, keeping battery modules within safe operating temperatures. - Lightweight Design

Optimized channels reduce material usage, contributing to overall vehicle weight reduction. - Predictable Flow & Pressure

For typical EV coolant flow rates, ensuring uniform cooling across all cells. - Compact Footprint

Continuous channels allow high-performance cooling without increasing battery pack size.

Results

Spherene's Adaptive Density Minimal Surface (ADMS) provides essential solutions for EV cooling plates, resulting in Extended Battery Range & Life through high thermal efficiency; Reduced Manufacturing Costs (BOM) via lightweight design; Enhanced Safety & Performance due to predictable, uniform cooling; and Increased Energy Density enabled by a compact, high-performance cooling footprint.

MOLDING

ADVANCED MOLDING. ACCELERATED PRODUCTION.

- Conformal dual-chamber cooling channels follow the part geometry for efficient heat extraction.

- Uniform cooling minimizes deformation and improves part quality and dimensional stability.

- Faster, more efficient cooling shortens cycle times, increasing throughput and reducing per-part costs.

- Lightweight, minimal-surface tooling reduces material use, machining time, and supports hybrid manufacturing.

- Dual-chamber architecture allows independent or alternating cooling/heating for process optimization.

- ADMS-based mold inserts replace traditional drilled cores, offering stronger structures while reducing material use, energy consumption, and tooling weight by up to 20%.

- Optimized thermal management improves process consistency and part quality in high-volume production.

- Lighter, more efficient tooling enhances sustainability and has demonstrated excellent performance in real manufacturing environments.

Results

A lighter, more efficient, and thermally optimized tooling system that delivers faster cycle times, higher part quality, lower costs, and improved sustainability—validated in real high-volume manufacturing environments.

Stay cool under pressure.

Explore how Spherene can transform your thermal designs