INTERIOR DFAM OPTIMIZATION

Smarter lattices, faster design cycles

Designing optimal lattices manually is time-consuming, prone to error, and slows down product development.

Conventional lattices often need many iterations before certification.

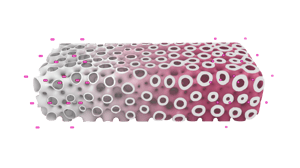

THE SOLUTION WITH SPHERENE

ADMS automatically generates load-adaptive, continuously graded, certifiable lattices directly in your CAD, reducing trial-and-error and accelerating time-to-market.

Key Benefits:

- Faster product design and fewer manual iterations

- Predictable mechanical performance for quicker approval

- Support-free, printable geometries

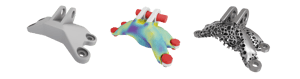

GE BRACKET: SPHERENE EDITION

Challenge: Design a lightweight titanium jet engine lifting bracket capable of withstanding extreme loads in multiple directions (vertical, horizontal, diagonal, torsional). Original part weighed 2,033 g.

Method:

- ADMS lattices where used to selectively remove material from low-stress regions while reinforcing critical load paths.

- Finite-element simulations guided lattice density to ensure predictable stiffness zones.

- Optimized with minimal support structures to reduce build time and material usage.

Results:

- Print mass: -7% vs. competition winner

- Support volume: -58%

- Engineering time: -64%

- Post-processing time: -80%

- Total cost savings: 49%

Impact:

Achieved lighter, certified, high-performance aerospace part with full structural integrity, demonstrating how simulation-driven lattice optimization can outperform traditional and even award-winning designs.

Other applications

ESA BRACKET

- Lattice optimization allows for faster certification by producing predictable, simulation-verified performance.

- Reduces the number of design iterations needed for structural validation, accelerating time-to-launch.

- Lightweight lattice structure improves payload efficiency while maintaining strength and durability under space loads.

- Demonstrates how ADMS lattices enable high-performance, reliable aerospace components that meet strict operational and regulatory requirements.

Watch video: sphereneRHINO Design Workflow ESA Satellite Bracket

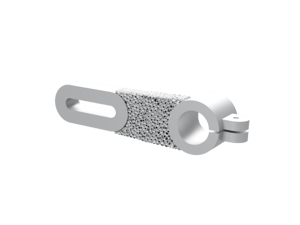

ANCHOR BRACKET: ACCESSORY MOUNTING

- Used in automotive, robotics, and film applications for mounting heavy accessories to tubular frames.

- Lattice-filled bridging volume optimizes weight-to-strength ratio, maintaining robustness while reducing mass.

- Allows for adjustable attachment points without over-engineering the structure

- Highlights how lattice optimization provides efficient, load-bearing designs for industrial and mechanical applications.