ADAPTIVE LIGHTWEIGHTING

Lighter, stronger, certified parts for faster next-generation designs

.png?width=300&name=GE_Bracket_square2%20(1).png)

EXCESS WEIGHT IN AREAS SUCH AS AEROSPACE, AUTOMOTIVE AND ROBOTICS APPLICATIONS LEADS TO:

-

Higher manufacturing and operational costs

-

Reduced efficiency and payload capacity

-

Limitations on design flexibility and performance

Traditional light weighting often requires trade-offs between strength, safety, and manufacturability, slowing down innovation.

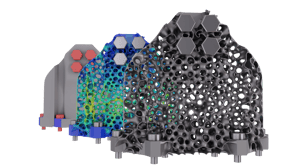

THE SOLUTION WITH SPHERENE

ADMS intelligently removes material where it isn’t needed, creating lighter, stronger, and certified parts.

Key Benefits:

-

Optimized for additive manufacturing while maintaining structural integrity.

-

Reduces part mass without compromising strength in critical areas.

-

Minimizes support structures, print time, and post-processing for faster, cheaper production.

-

Lowers energy use and emissions by reducing weight, enabling higher payload and longer range.

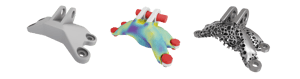

ESA SATELLITE BRACKET

Satellite structures must minimize weight to reduce launch costs while maintaining certifiable mechanical performance under extreme static and dynamic loads.

Method

Using Spherene’s ADMS, the bracket’s geometry was optimized by removing non-critical material and reinforcing load-bearing areas with lattice structures tuned for stiffness.

Results

- Achieved 40% weight reduction compared to the baseline design.

- Maintained full structural integrity and load capacity under ESA’s qualification criteria.

- Reduced design iterations due to simulation-verified lattice performance, accelerating the certification process.

Other applications

AUTOMOTIVE: LOW CONTROL ARM

- Re-engineered with ADMS to remove mass from low-stress regions, reducing overall component weight.

- Lighter control arms translate into lower fuel consumption and reduced CO₂ emissions.

- Weight savings allow manufacturers to meet stricter efficiency regulations without sacrificing safety or durability.

- Simplified lattice design shortens development cycles and reduces material costs.

GE BRACKET: AEROSPACE

- Original goal: minimize weight while meeting extreme load requirements.

- With ADMS lattices, it removed material from low-stress regions, maintaining strength in critical zones.

- Achieved 7% lower print mass compared to the official competition winner.

- Reduced support structures, improving manufacturing efficiency.

- Demonstrates how lattice optimization contributes to lightweight, certified aerospace parts.