ADAPTIVE STRENGTH WHERE IT MATTERS

Precision tuning of mechanical properties

TRADITIONAL LATTICE STRUCTURES OFTEN LACK LOCAL CONTROL, FORCING DESIGNERS TO CHOOSE BETWEEN STRENGTH AND FLEXIBILITY.

This trade-off can lead to over-engineered components that are either too rigid or insufficiently robust.

THE SOLUTION WITH SPHERENE

ADMS enables precise local tuning of density and stiffness, allowing for tailored performance in different zones of a component. This approach ensures that each area meets specific mechanical requirements without unnecessary material usage.

Key Benefits

-

Strength where it counts

Densify lattices in key spots, saving material everywhere else. -

Flex where you need it

Adaptive zones stay compliant for better overall performance. -

Performance you can trust

Simulation-backed designs behave reliably under load. -

Design made easy

Streamlined workflows cut time and complexity.

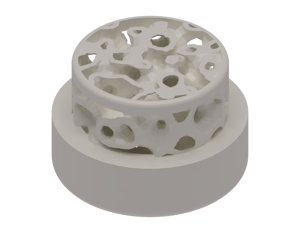

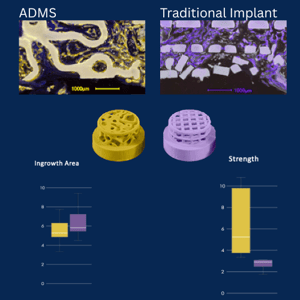

IMPLANTS: BONE-MIMICKING SCAFFOLDS

Researchers tested Spherene-designed scaffolds with murine iPSCs in a rabbit calvarial defect model to evaluate how bone-mimicking lattices enhance integration, healing, and mechanical performance versus conventional implants.

Method

- Scaffold Design: Lattices mimicked natural bone geometry, balancing strength and porosity for optimal cell growth.

- Cell Seeding: Murine iPSCs loaded onto scaffolds to promote bone regeneration.

- In Vivo Testing: Implanted in rabbit calvarial defects; monitored healing, integration, and bone growth.

- Simulation & Validation: Finite-element and flow simulations guided lattice design for predictable mechanics and nutrient transport.

- Analysis: Post-implantation imaging and histology quantified bone growth, scaffold integration, and mechanical performance.

Results

- Enhanced Bone Growth: Scaffolds promoted faster and more uniform bone regeneration.

- Structural Integration: Lattices supported proper load distribution and minimized stress concentrations.

- Predictable Performance: Simulation-driven designs translated reliably from model to in vivo results.

- Optimized Material Use: Bone-mimicking geometries achieved strong mechanical support while reducing material footprint.

Kessler, F., Ghayor, C., Bhattacharya, I., & Weber, F. E. (2024). Murine iPSC-loaded scaffold grafts improve bone regeneration in a rabbit calvarial defect model. International Journal of Molecular Sciences, 25(4), 1234–1245.

Other applications

FRAMAS SHOE LAST EXPLORATION

- Spherene enables tuned flexibility in the shoe last, allowing different regions to deform appropriately during shoe manufacturing and testing.

- Balances rigidity for mold support with compliance where needed, improving the accuracy of the shoe shape and fit.

- Reduces material waste and streamlines iterations by allowing local stiffness adjustments directly in the last.

- Supports rapid prototyping and customization for diverse foot shapes and shoe designs.

This video shows the process Framas took to explore with ADMS.

In partnership with Framas (@Framas)

Visual: Shoelast exploration

Left to right: Spherene as infill, partially closed, thickened up and as lattice.

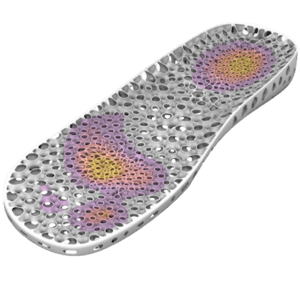

3DFIT INSOLES & CUSTOM SHOES

- Spherene is tailored to create adaptive cushioning zones that respond to varying pressure across the foot.

- Harder zones provide support under high-load areas, softer zones enhance comfort and shock absorption.

- Customizable for individual foot anatomy or activity type, improving both performance and comfort.

- Optimized Spherene designs reduce material usage while maintaining durability over repeated cycles.

In partnership with 3DFIT (3DFIT.ch)

Visual: Personalized shoes powered with Spherene ADMS technology.